Need help finding a machine?

We will gladly assist you in making the right decision to achieve your business goals

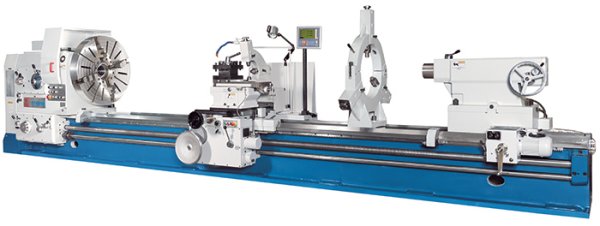

HEAVY-DUTY LATHE

DL E Heavy 620/1500With the machines of the DL E Heavy series, you can machine really large turning diameters and workpiece lengths. This lathe series is the solution for conventional machining of workpieces up to 8000 mm (315 in.) in length and over 1600 mm (63 in.) in diameter. The particularly wide and heavily ribbed machine bed takes heavy workpiece weights. Powerful motors drive the main spindle via a finely adjustable multi-disc clutch. The rapid traverse in the support is particularly effective with large bed lengths and the heavy tailstock is also moved with a motor drive.

| Working Area | |

|---|---|

| Workpiece length (max.) | 59 in |

| Turning diameter over bed | 49 in |

| Turning-Ø over support | 35 in |

| Workpiece weight (max.) | 13200 lbs |

| Bed width | 30 in |

| Max. weight capacity (between centers) | 13200 lbs |

| Max. weight capacity (on chuck) | 3300 lbs |

| Travels | |

|---|---|

| Travel X-axis | 24.8 in |

| Travel Z-axis | 51 in |

| Travel Z1-axis | 12 in |

| Swing range of top slide | ± 180° |

| Headstock | |

|---|---|

| Spindle speeds (right) | 3.15 rpm - 315 rpm |

| Spindle speeds (left) | 4 rpm - 315 rpm |

| Spindle bore | 5.1 in |

| Spindle mount | A2-15 |

| Rapid Feed | |

|---|---|

| Rapid feed X-axis | 73.62 in/min |

| Rapid feed Z-axis | 147.24 in/min |

| Feed | |

|---|---|

| Feed X-axis | 0.00252 in/R - 0.47244 in/R |

| Feed Z-axis | 0.00126 in/R - 0.23622 in/R |

| Feed Z1-axis | 0 in/R - 0.12 in/R |

| Threading | |

|---|---|

| Threading, metric | 1 mm - 120 mm |

| Threading, diametric | (42) 30 - 1/4 DP |

| Threading, module | 0.5 mm - 60 mm |

| Threading, whitworth | (48) 05 - 60 TPI |

| Tailstock | |

|---|---|

| Tailstock quill diameter | 6 in |

| Tailstock quill taper | metric 80 |

| Tailstock quill stroke | 12 in |

| Tailstock traverse adjustment | ± 0.1 in |

| Drive Capacity | |

|---|---|

| Motor rating main drive | 29.5 Hp |

| Measures and Weights | |

|---|---|

| Overall dimensions (length x width x height) | 182 in x 72 in x 71 in |

| Weight | 21450 lbs |

3-axis position indicator

Mounted behind the bridge, this unit ensures automatic central lubrication, which minimizes service requirements and greatly increases machine reliability

Explore the range of compatible accessories in stock

We will gladly assist you in making the right decision to achieve your business goals

All machines need an occasional pit stop. With our all-encompassing plans for service, training and installation you always will get the best possible performance from your KNUTH machines.

View Services

Get a first-hand impression at one of our facilities! Many machines in our portfolio are always in stock and available for demonstration.

Book a Demo

We have received your request and appreciate your interest! Our sales representative will get in touch within 1 business day.

Please refresh the page and try submitting the form again.

We have received your request and appreciate your interest! Our sales representative will get in touch within 1 business day.

Please refresh the page and try submitting the form again.