Need help finding a machine?

We will gladly assist you in making the right decision to achieve your business goals

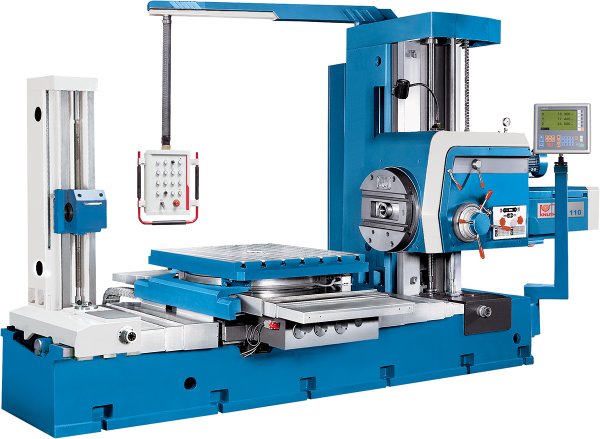

CONVENTIONAL MILLING AND BORING MACHINE

BO 110The BO series of conventional boring-milling machines is designed for horizontal, multi-sided drilling and milling of workpiece weights of up to 2.5 tons. The stand is fixed, while the table can move and rotate 360°. The drill head moves on the column and the spindle has a long stroke on the W-axis. Conventional boring mills also have a facing slide with a long stroke, which extends the application to include boring. High drive power and automatic feeds on all axes with rapid traverse enable efficient machining and short non-productive times.

| Working area | |

|---|---|

| Drilling capacity | 50 mm |

| Table set up area | 1100 mm x 960 mm |

| Table load capacity | 2500 kg |

| Table rotation range | 4 x 90° |

| Spindle axis-to-table surface distance | 0 mm - 900 mm |

| Rotation speed of rotary table | 1 1/min |

| Travels | |

|---|---|

| Travel X-axis | 900 mm |

| Travel Y-axis | 900 mm |

| Travel Z-axis | 900 mm |

| Travel W-axis | 600 mm |

| Facing slide travel | 180 mm |

| Headstock | |

|---|---|

| Speed range | 8 1/min - 1000 1/min |

| Spindle diameter | 110 mm |

| Spindle torque (max.) | 1225 Nm |

| Spindle mount | SK 50 |

| Facing slide speed | 4 1/min - 200 1/min |

| Feed force, axial (max.) | 12,25 kN |

| Facing slide torque (max.) | 1960 Nm |

| Rapid feed | |

|---|---|

| Rapid feed X-axis | 2500 mm/min |

| Rapid feed Y-axis | 2500 mm/min |

| Rapid feed W-axis | 2500 mm/min |

| Feed | |

|---|---|

| Feed X-axis | 0,01 mm/R - 6 mm/R |

| Feed Y-axis | 0,01 mm/R - 6 mm/R |

| Feed Z-axis | 0,01 mm/R - 6 mm/R |

| Feed W-axis | 0,01 mm/R - 6 mm/R |

| Facing slide feed | 0,08 mm/min - 12 mm/min |

| Accuracies | |

|---|---|

| Read-out accuracy (optic) | 0,01 mm |

| Counter-bore accuracy | H7 Ra-1,6 µm |

| Drive capacity | |

|---|---|

| Motor rating main drive | 7,5 kW |

| Motor rating hydraulic pump | 0,37 kW |

| Measures and weights | |

|---|---|

| Overall dimensions (length x width x height) | 4,88 m x 2,45 m x 2,75 m |

| Weight | 11500 kg |

3-axis position indicator

Explore the range of compatible accessories in stock

We will gladly assist you in making the right decision to achieve your business goals

All machines need an occasional pit stop. With our all-encompassing plans for service, training and installation you always will get the best possible performance from your KNUTH machines.

View Services

Get a first-hand impression at one of our facilities! Many machines in our portfolio are always in stock and available for demonstration.

Book a Demo

We have received your request and appreciate your interest! Our sales representative will get in touch within 1 business day.

Please refresh the page and try submitting the form again.

We have received your request and appreciate your interest! Our sales representative will get in touch within 1 business day.

Please refresh the page and try submitting the form again.