Intensive collaborative development

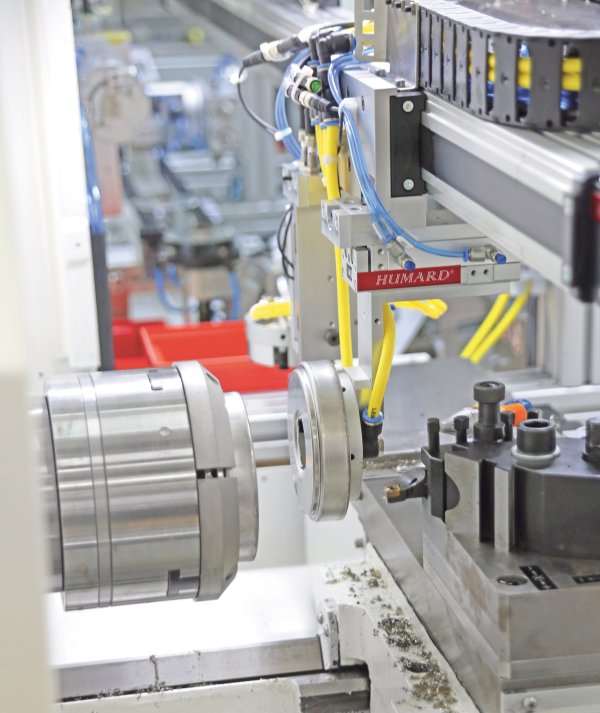

“The development of an automation solution can be compared to the creation of a tailored suit. It must be adjusted for an exact fit that meets all customer requirements,” says F. Carabotti. The sooner Humard is included in the development process, the better is the outcome. By close cooperation with the customer’s respective departments during engineering, we can make meaningful adjustments to adapt the product design to the requirements set by the production process. “This consultation is a significant part of the development process,” emphasized Carabotti. “Together with our customer, we design the entire production process. Then we will implement the process completely up to the final delivery of the turnkey system.” Humard also assumes responsibility for technical components, like machine tools or certain robots, which it purchases from thoroughly vetted partners. The Swiss engineering firm focuses mainly on design, assembly, programming, and service. Major basic components, like frames for the modules, are produced internally or by an affiliated company. In addition, they are supported by a large network of proven suppliers. Due to the enormous and constantly growing range of available technologies and machines, they continuously partner with new businesses that first must pass their rigorous qualification testing. the lathe was its a total cycle time of just 7s, as this is critical to the productivity of the entire production line. Since Humard could not find a ready solution in the market, the Swiss company started looking for a supplier that could retrofit a suitable standard machine to achieve the required features.