AHK M 2160 NC

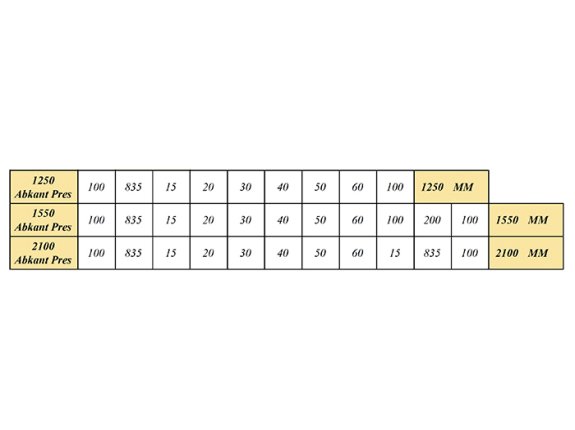

The AHK M series was developed as a modern, inexpensive NC alternative to CNC press brakes. Many operators are familiar working without CNC programming, and this model series combines proven technology with modern safety standards. The back gauge in the X- and R-axes and the depth gauge in the cylinders can be positioned directly using the touchscreen, or bending sequences can be stored in the NC control for automatic operation. The series is convincing in the production of workpieces with recurring materials and contours.

- Stress-relieved welded steel construction

- Top beam with torsion shaft

- NC control with touch-screen HMI

- Back gauge with X and R axes

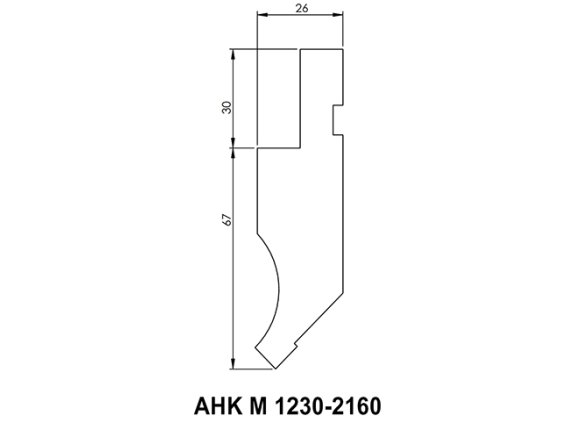

- European-style male die