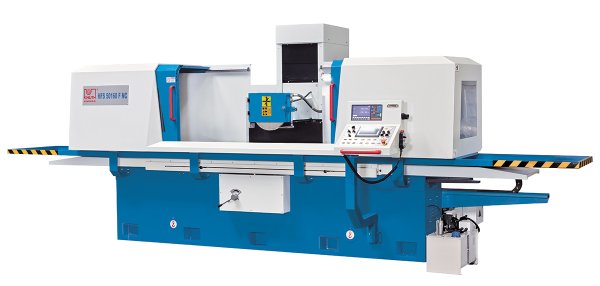

HFS 60160 F NC

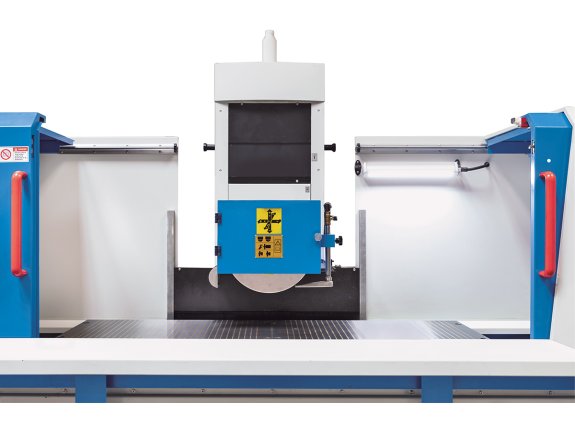

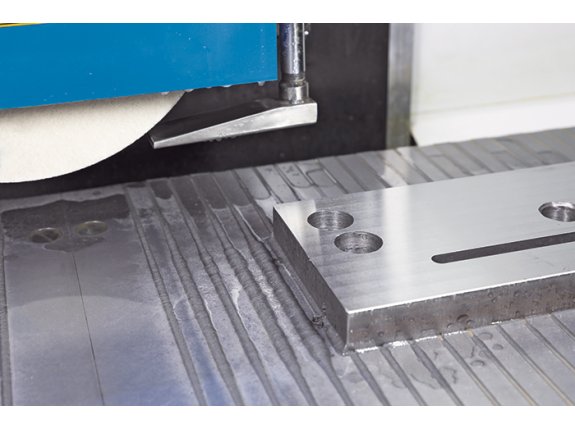

This series of surface grinders processes large and heavy workpieces with tolerances as required for precision surface grinding or for the preparatory processing step of lapping or polishing. The machine frame is designed in a cross-bed design with a movable column. This construction enables a long table guidance and thus the optimal introduction of weight force over the entire work area. The ability to switch between automatic or manual operation extends the scope for sample production, repair and training.

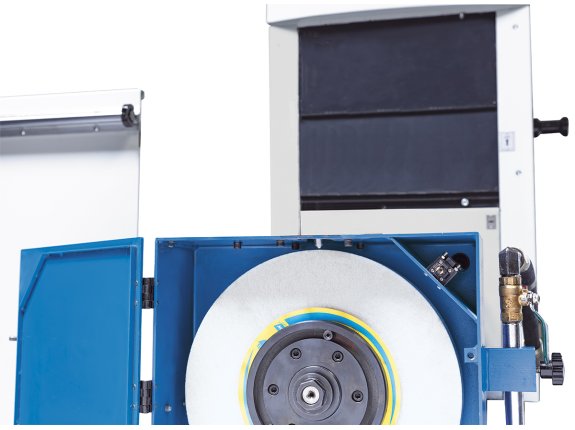

- Moving column design for maximum stability

- Magnetic clamping plate with built-in demagnetizing function

- Siemens Smart Line PLC control with grinding cycles

- NC-controlled Y/Z axes driven by servo motors

- User-friendly HMI with touchscreen

- Electronic handwheel for Y/Z axes