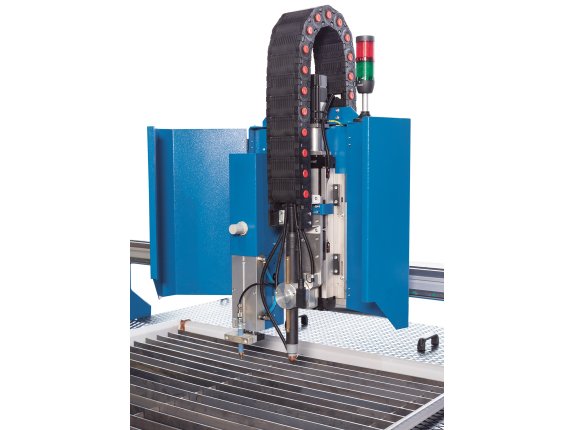

PLASMA CUTTING MACHINE

Plasma-Jet AirPro Compact 2010The machines in the Plasma-Jet AirPro compact series offer good cutting quality with minimal operating costs. These economical cutting systems for air plasma sources were developed as a cost-effective solution for custom and small-series manufacturing; their compact design and low footprint makes them the perfect choice for workshops. The machines in this series are easy to operate and extremely reliable.

- Compact design, fast setup

- For air plasma sources by Hypertherm or Kjellberg (optional)

- EtherCAT technology for best CNC performance

- Professional Nesting Software solution included

- With vacuum table, also optional water cutting table