Thermoforming Automation for America

“Our machines process PP, PP-EVOH-PP, PS or APET plastic films that are fed direct from rolls,” explained Founder and Chief Executive Officer, Norbert Rohde. Since 1996 his business designs and manufacturers automated thermoforming equipment in series production. “The film is automatically fed into the thermoformer, where it is heated. Using compressed air and the appropriate die, the heated film will then be pressed into its final shape.” After a cooldown phase, the forms are punched out of the surrounding film and stacked for transportation to the next stage. For their international customers, Rohde and his team produce perfectly fitted dies that meet the exact requirements of the final beakers, dishes or lids. About eight machines with up to 20 different thermoforming dies are sent from this plant in the Northern German Schleswig-Holstein region in various countries of the world. A big demand for these machines exists in South and Central America, and increasingly in the USA and Canada. “Our portfolio is a good match for North American markets,” added Norbert Rhode.

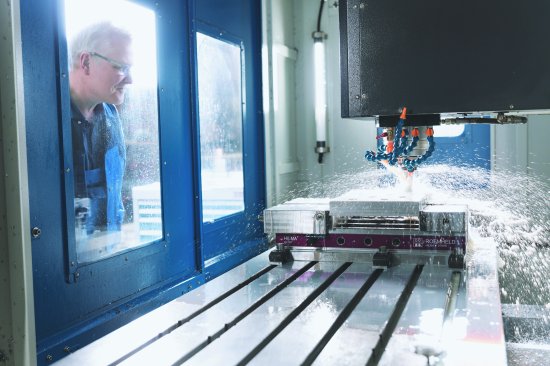

Heat the film, shape it, and cool it − it seems to be very easy to make beakers and dishes for the food industry. However, the technology behind it is very complex and working with film thicknesses between 100 micrometer and 0.118” requires extreme precision. The lasting functionality of thermoforming systems can only be guaranteed, if this extreme precision is integrated during their construction.