Sometimes fate plays a role

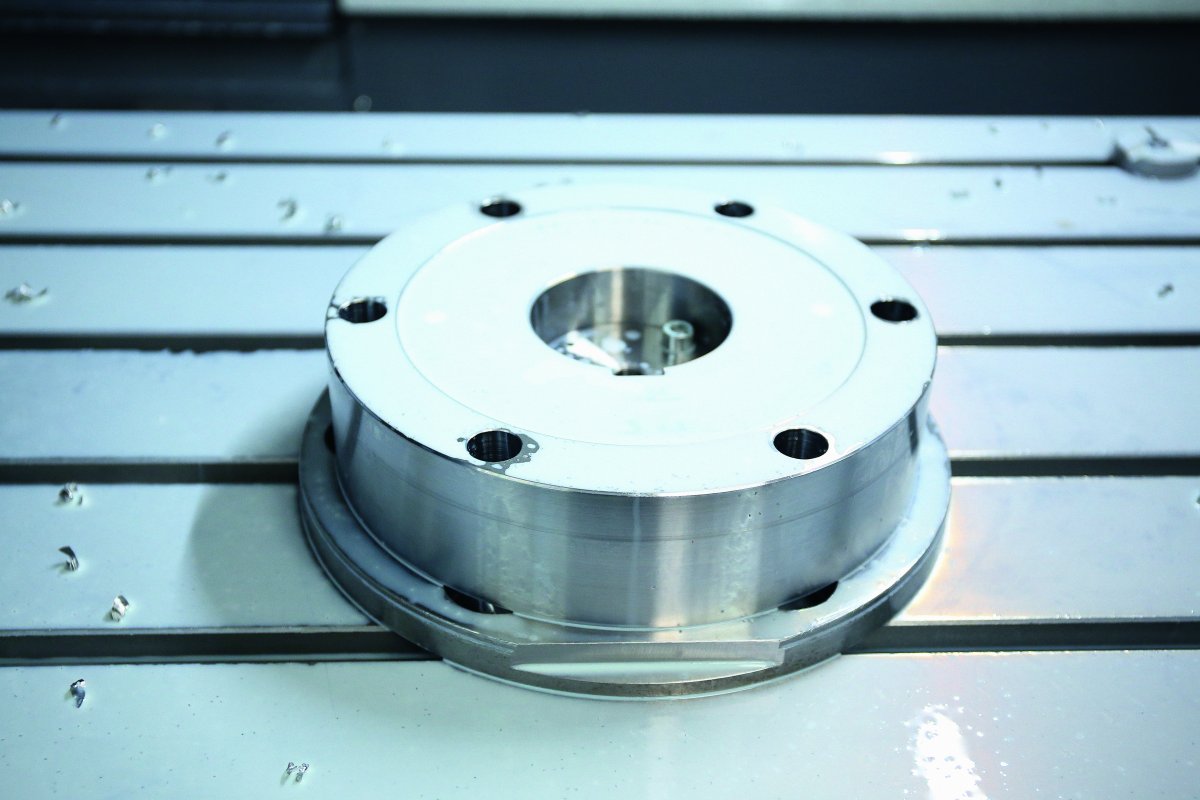

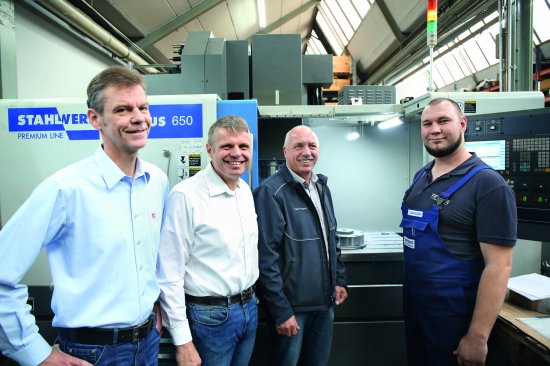

Fate not only plays a role in crime thrillers, but also when it comes to making investment decisions. The Tietjen team quickly reached agreement with machine supplier Knuth about the selection of a 3-axis machining center with a tool changer. „One of the last demonstrations involved a tool change and how it is mapped in the control system. As the whole thing appeared to be complicated and was taking somewhat longer, some of us wandered around the Knuth demonstration center. And as luck would have it, we bumped into Mr. Bartsch from Siemens, who was setting up a Sinumerik control system with ShopMill at another machine. Right from the outset, it was clear that the Sinumerik operations were smoother, more user-friendly and simpler. This aroused our interest. We asked if we could see more, and then made a quick decision: We would be equipping our new machining center with a Sinumerik control system“, recalled Peter Wagner, Head of Production. However, this turned out to be easier said than done. Michael Schaaf, Technical Manager of the STAHLWERK KNUTH brand: „The 3-axis machining center was not supplied with Sinumerik. However, we made it possible for the customer, and thanks to the support from Siemens, the machining center was installed with a Sinumerik 828D with ShopMill. For batch sizes of between 3 and 5 up to maximum of 50 parts, Tietjen really does benefit from the flexible programming options and the significantly simpler operation of Sinumerik.“ Installing the machining center in the narrow factory hall presented a challenge. With the plant still operational, machines had to be moved around, the floor of the hall opened up and a solid foundation poured. The machining