HOT DEAL

This machine is part of our seasonal sale.

Roturn 400 M

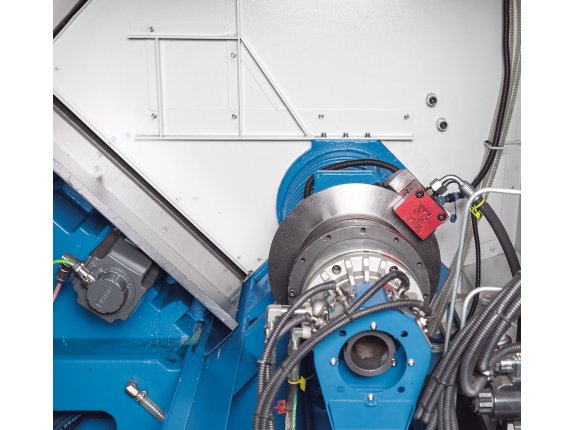

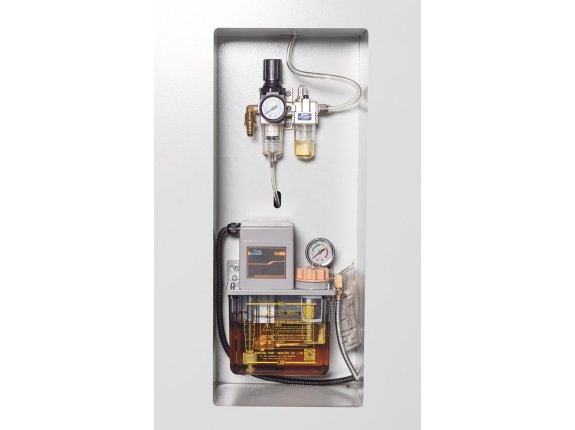

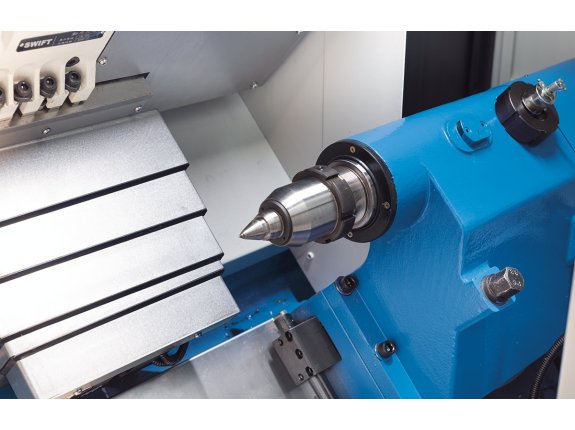

This ROTURN M Series machine has all the features of a classic compact CNC production lathe. Modern, rigid inclined-bed design with linear guides on all axes, powered collet chuck and hydraulically moved tailstock quill. Including C-axis, 12-station tool turret, and driven tools for axial and radial drilling and milling A link conveyor for chip removal and a highly efficient coolant system complete the equipment package. The Siemens 828 D Basic control meets all requirements for advanced control technology.

- Powerful main spindle motor

- High-resolution C-axis

- 12-station tool turret with driven tools

- Chip conveyor included

- Siemens 828 D control