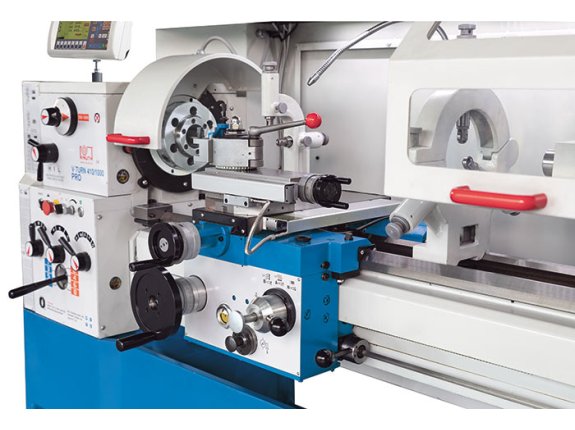

V-Turn 410 PRO

The newly designed PRO models of our bestseller V-Turn convince with improved ergonomics and more safety. Equipped with an inverter and a high-performance spindle motor, they can easily reach 3,000 revolutions per minute. Workpieces with a small diameter can thus be efficiently machined. However, the models also offer strength and stability for heavier machining. The built-in function of the constant cutting speed, which adapts the spindle speed to the diameter when facing, enables turning results that are comparable to CNC machines to be achieved.

- Ergonomic machine housing

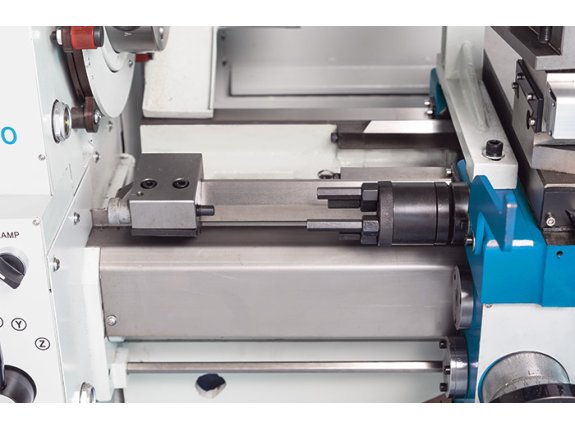

- Improved apron with automated feed

- Constant cutting speed

- High spindle speed and motor power

- Roller bearings from world-leading manufacturer NSK