Renishaw OMP 40 Workpiece Measuring

SKU: 252820

Renishaw OMP 40 Workpiece Measuring

Connection for 4th axis (wiring only and axis chart)

SKU: 253019

Connection for 4th axis (wiring only and axis chart)

Siemens Function: P25: 3D Simulation

SKU: 253378

Siemens Function: P25: 3D Simulation

Siemens Function: P13: Residual Material Detection

SKU: 253379

Siemens Function: P13: Residual Material Detection

Siemens Function: P22: Simultaneous Recording

SKU: 253380

Siemens Function: P22: Simultaneous Recording

Renishaw Tool Setter TS27R

SKU: 253386

Renishaw Tool Setter TS27R

Measuring Cycles

SKU: 253438

Measuring Cycles

Renishaw OTS wireless tool setter (OTS)

SKU: 253598

Renishaw OTS wireless tool setter (OTS)

Ø 210mm 4th axis (4th axis, servo motor, driver, air brakes)(Si)

SKU: 253606

Ø 210mm 4th axis (4th axis, servo motor, driver, air brakes)(Si)

Ø 250mm 4th axis (4th axis, servo motor, driver, air brakes)(Si)

SKU: 253607

Ø 250mm 4th axis (4th axis, servo motor, driver, air brakes)(Si)

preparation for Renishaw OMP40

SKU: 253613

preparation for Renishaw OMP40

manual tailstock ST-210T for rotary table for X.mill

SKU: 253619

manual tailstock ST-210T for rotary table for X.mill

manual 8'' chuck for rotary table for X.mill

SKU: 253623

manual 8'' chuck for rotary table for X.mill

Upgrade from 10.4” to 15” touch screen (for PPU260 or higher)

SKU: 253674

Upgrade from 10.4” to 15” touch screen (for PPU260 or higher)

Renishaw OMP 60 workpiece measuring system (BT40)

SKU: 253681

Renishaw OMP 60 workpiece measuring system (BT40)

200 mm diam. 4th & 5th axis for Vector 650/850/1000 (Si)

SKU: 253682

200 mm diam. 4th & 5th axis for Vector 650/850/1000 (Si)

Spindle speed upgrade to 12000 rpm, belt-type

SKU: 253781

Spindle speed upgrade to 12000 rpm, belt-type

Top cover for Vector 1300-1600

SKU: 253783

Top cover for Vector 1300-1600

Upgrade from 828D PPU260 to 840DSL IPC447E 10.4" for Vector

SKU: 253835

Upgrade from 828D PPU260 to 840DSL IPC447E 10.4" for Vector

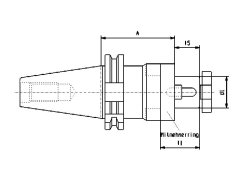

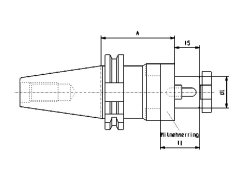

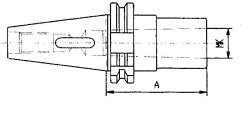

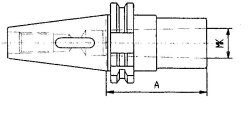

Upgrade for ATC from 24 to 30 tools (BT40) for Vector 1300-1600

SKU: 253843

Upgrade for ATC from 24 to 30 tools (BT40) for Vector 1300-1600

Ø320 mm, 4th axis (4th axis, servo motor, driver, hydr. brakes)

SKU: 254179

Ø320 mm, 4th axis (4th axis, servo motor, driver, hydr. brakes)

Manual tailstock for Ø320 mm rotary table

SKU: 254180

Manual tailstock for Ø320 mm rotary table

Manual chuck, 12'', for rotary table

SKU: 254181

Manual chuck, 12'', for rotary table